Abstract

Today, a nation’s strength is often reflected in the scale and sophistication of its infrastructure. In a country like India, with its diverse and complex geological conditions, executing tunnelling projects presents critical engineering challenges. Despite these difficulties, tunnels play a crucial role in modern infrastructure development, particularly in metro systems, conventional railways, and high-speed rail projects. Tunnelling remains a vast and rapidly evolving domain within the construction industry. It is regarded as one of the most complex construction methods due to the unpredictable nature of rock masses encountered during execution.

The New Austrian Tunnelling Method (These geological uncertainties bring a range of challenges, including wedge formations, shear zones, loose debris, underground water channels, low overburden, and heavy water ingress during tunnelling operations. The effective execution of tunnelling necessitates the adoption of precise, well-engineered methods that not only ensure construction safety but also help optimise timelines and reduce project risks.

NATM is recognised as the most effective tunnelling technique, particularly in regions with challenging geological conditions. This tunnelling method follows an observational approach, which primarily focuses on the continuous monitoring and adaptation during construction.

This paper provides an overview of the New Austrian Tunnelling Method (NATM) and outlines the construction sequences associated with this technique. In addition, it examines the role of NATM in the successful execution of complex rail infrastructure projects, illustrated through relevant case studies that highlight its practical applications and advantages in adverse geological conditions.

Introduction of the New Austrian Tunnelling Method

The New Austrian Tunnelling Method (NATM) was introduced in Austria between 1957 and 1965 as a modern approach to tunnel construction. The term “NATM” was introduced in 1962 during the Salzburg XXII Geomechanics Colloquium to distinguish it from the previous ‘Austrian Tunnelling Method. The method was shaped by the contributions of engineers Ladislaus von Rabcewicz, Leopold Müller, and Franz Pacher.

NATM follows the principle of mobilising the strength of the surrounding rock mass to support the tunnel structure. Rather than relying solely on rigid support systems, NATM incorporates continuous monitoring and adaptive strategies which enable the ground to maintain tunnel stability under varying geological conditions.

For example, Tunnel excavation in the Himalayan region presents geological variability, as rock conditions often change every 100 meters. This makes it challenging to apply a uniform design across the entire stretch. In such situations, the New Austrian Tunnelling Method (NATM) offers a practical solution due to its observational approach. By continuously monitoring ground conditions during excavation, NATM allows for the adjustment of support systems and construction techniques in response to the specific geological context encountered at different sections.

Principles of NATM

The New Austrian Tunnelling Method (NATM) is grounded in the principles of rock mass behaviour under load and continuous performance monitoring during the construction process. Rather than prescribing a fixed set of excavation and support techniques, NATM focuses on flexibility and adaptability, which helps to tailor the support systems to the requirements of the actual site condition. NATM involves interpreting real-time data such as ground convergence, divergence, and rock stability to make informed decisions about the type and extent of support required. The method prioritises the interaction between the surrounding ground and the installed support, which is paramount to ensure and optimise structural safety and material usage.

Primarily, NATM follows 7 principles, which are mentioned below:

- Utilisation of the Rock Mass’s Natural Load-Bearing Capacity: NATM uses the natural strength of the surrounding rock mass as a fundamental element of tunnel support. Rather than relying entirely on rigid structural systems, the method allows the ground to act as a self-supporting structure. The application of primary support, which includes shotcrete, rock bolts, and wire mesh, is designed to stabilise the rock mass in a way that enables it to carry its own load effectively, which minimises the need for heavy, pre-designed reinforcements.

- Shotcrete Application for Initial Support:

To minimise loosening and excessive deformation of the surrounding rock, a thin layer of shotcrete is applied immediately after each excavation advance. This early application of shotcrete helps to stabilise the exposed rock surface, controls displacement, and preserves the integrity of the surrounding ground. It acts as a flexible support layer that conforms to the rock surface and enables the ground to contribute to the overall stability of the tunnel.

- Monitoring and Instrumentation:

Accurate measurement of deformation is a fundamental aspect of NATM. The method relies on continuous monitoring to assess ground behaviour and the effectiveness of the support systems. For the fine assessment of the ground behaviour, a range of sophisticated instrumentation is installed within the tunnel lining, the surrounding ground, and boreholes. These instruments measure parameters such as displacement, stress, and convergence, and provide real-time data that guides necessary adjustments to the excavation and support strategy.

- Flexible Support Systems

NATM employs a flexible support approach, where the primary lining (arch and walls) is intentionally kept thin to respond effectively to the current ground conditions. Instead of relying on a thick concrete lining for stability, the method employs an active support system which is composed of rock bolts, wire mesh, and steel ribs. This combination provides sufficient reinforcement, which reduces the deformation of the surrounding rock mass.

- Closure of the Invert to form a Load-Bearing Ring

It is imperative to achieve the closure of the invert, which is also referred to as the bottom portion of the tunnel. By connecting the tunnel arch with the invert, a complete load-bearing ring is formed, which enhances overall structural stability and evenly distributes ground pressure. Leaving the invert open, even temporarily, can lead to uncontrolled deformation or ground settlement.

- Contractual Flexibility and Adaptability:

One of the essential requirements for implementing NATM effectively is a contractual framework that allows flexibility. Since NATM relies on real-time monitoring and observational data, modifications to support systems or construction methods may be necessary as ground conditions change. Such adaptive decision-making is only feasible when the contract provisions permit variations in design, scope, and construction techniques without causing delays or disputes. Therefore, contractual arrangements must be structured to accommodate the dynamic nature of NATM-based tunnelling.

- Rock Mass Classification as a Basis for Support Design: In NATM, the classification of the rock mass plays a key role in identifying appropriate support measures. Various standardised rock classification systems, such as RMR (Rock Mass Rating) or Q-system, are used to assess the quality and behaviour of the ground. Taking reference from these classifications, the tunnel alignment is divided into distinct rock classes, each associated with predefined support strategies. These guidelines help engineers select suitable reinforcement elements, such as shotcrete thickness, rock bolt spacing, and the use of steel ribs, tailored to the geotechnical conditions encountered.

Sequence of NATM

The New Austrian Tunnelling Method (NATM) follows a systematic sequence for installing the initial support system, which relies on the real-time data derived from the monitoring of the ground profile.

- Profile Marking

Profile marking helps to achieve the designed tunnel profile. This is a crucial element in the NATM or sequential excavation method. The primary objective of profile marking is to identify the minimum excavation boundary on the tunnel face, which ensures that the excavation remains within the planned limits. Profile marking also helps to prevent overbreaks, minimises material loss, and ensures structural stability.

- Face Drilling

Following the profile marking, the face drilling technique is used. This process involves drilling holes in a specific pattern on the tunnel face to facilitate controlled blasting or mechanical excavation. The primary objective of this process is to create uniform fragmentation of the rock, minimise overbreak, and maintain ground stability. Some of the common patterns of face drilling include V-cut, wedge cut, or fan cut arrangements.

- Charging and blasting

Charging and blasting is the process of placing and initiating explosives within drilled holes to fragment the rock for excavation. In the NATM process, charging is typically carried out manually. The explosives are inserted into the drilled holes in a specific sequence to ensure controlled blasting, minimise overbreak, and maintain the integrity of the surrounding rock.

Defuming:

This process is carried out after the blasting is completed. Defuming is used to expel the harmful gases that are released during the blasting phase. Due to their lower density, these gases typically accumulate along the crown (topmost portion) of the tunnel. To manage this, a dedicated ventilation system is installed, typically comprising ventilation ducts positioned along the tunnel crown and jet fans to facilitate airflow. The system is designed to continuously supply fresh air while extracting hazardous fumes and dust particles generated by the blast.

- Mucking

The debris generated after blasting is referred to as muck. The process of collecting and removing this material from the tunnel is known as mucking. The vehicles to facilitate this process are based on the available working space within the tunnel. Once mucking is completed, thorough checks are performed to identify the cracks or loose material.

- Geological Mapping: This process involves examining the exposed tunnel face to assess the type of rock and the number and orientation of joints, fractures, and discontinuities. This process is repeated after each excavation cycle. During this process, the geologist prepares a face log, documenting key geological features, rock mass classification, and any variations from the expected ground conditions, which help the geologists to evaluate whether the originally designed support system is adequate for the encountered conditions. Further excavation is carried out based on the data acquired from the inspection of the tunnel face.

- Face Sealing Shortcrete

The process of applying a thin layer of mortar on the excavated area of the tunnel is called face sealing concrete. This layer is imperative to prevent the loose material from falling. Depending on the geological conditions and stability of the exposed surface, a minimum of 30 mm to a maximum of 50 mm thickness of sealing shotcrete is typically applied.

- Installation of 3D Monitoring Targets:

As the excavation moves forward, it is necessary to assess the performance of the tunnel support syste,m which enables engineers to determine whether the installed support is adequate for the prevailing ground conditions. In this process, on the different parts of the tunnel, including crown, sidewalls, and invert, after each excavation cycle. Following the installation, the readings are collected at regular intervals to detect any movement or deformation in the tunnel lining. The collected data is analysed to identify convergence, divergence, or any structural shifts which allow timely interventions if the observed deformations exceed acceptable thresholds.

- Installation of Lattice Girder

Following the application of a sealing shotcrete layer, the process of erecting the lattice girder is initiated. With the help of a total station, which is a modern surveying instrument, the marking is done of designated positions for placing the lattice girder in accordance with the tunnel design profile. Lattice girders serve as part of the initial support system in NATM. They help maintain the shape of the tunnel cross-section. Following this process, the lattice girders are connected with the existing support system by embedding them within additional layers of shotcrete.

- Shotcreting: Shotcreting involves spraying concrete onto the tunnel surface using compressed air through a high-pressure nozzle. This technique provides immediate ground support and surface stabilisation.

There are two primary types of shotcrete used in tunnelling:

- Sealing Shotcrete: This is applied immediately after excavation, and this is a thin layer that prevents loose rock or soil from falling.

- Main (Structural) Shotcrete: This is applied after the installation of initial support elements such as lattice girders; this thicker layer is designed to absorb and distribute the loads imposed by the surrounding ground. The thickness of it depends on the rock composition.

- Application of Rock Bolting:

In NATM, Rock Bolting acts as an initial support system. This process is used to strengthen the rock mass and integrate it with the applied shotcrete lining. Rock bolts are installed through the shotcrete and into the surrounding rock. The primary purpose of rock bolting is to “stitch” the rock mass and the shotcrete lining together. This integration helps control displacement and discontinuities, and improves the overall load-bearing capacity of the tunnel cross-section.

NATM vs TBM: A Comparative Analysis

| Criteria | Tunnel Boring Machine (TBM) | New Austrian Tunnelling Method (NATM) |

| Definition | This is mechanized method which employs a specialised machine to excavate circular tunnels in a continuous manner. | NATM is a conventional method which relies on the observational approach, using sequential excavation and ground support installation. |

| Best Suited For | Long tunnels with uniform geology; high-volume, high-speed excavation. | Tunnels in heterogeneous or complex geological conditions; short to medium lengths. |

| Excavation Method | Continuous, full-face mechanical excavation. | Sequential excavation. |

| Tunnel Shape | Generally circular due to the shape of TBM cutterheads. | Flexible; can be adapted to various shapes as required by design. |

| Speed of Excavation | High, especially in homogeneous and stable ground. | Moderate to low; slower due to multiple phases and monitoring. |

| Initial Support | Pre-installed lining segments as the TBM advances. | Shotcrete, rock bolts, wire mesh, lattice girders are applied progressively based on ground response. |

| Monitoring and Flexibility | Limited real-time adaptability once tunnelling starts. | High adaptability; support is adjusted based on ground behavior observed during excavation. |

| Cost Implications | High capital cost due to machinery and logistics; cost-effective for long tunnels. | Lower initial cost; better suited for shorter tunnels or tunnels with variable geology. |

| Manpower Requirement | Lower manual intervention; more automation. | Higher manpower needed for sequential excavation and support. |

| Construction Space | Requires large launching and retrieval shafts. | Can be executed in constrained spaces with limited access. |

The Application of NATM in India’s Major Rail Infrastructure Projects:

- Udhampur-Srinagar-Baramulla Rail Link

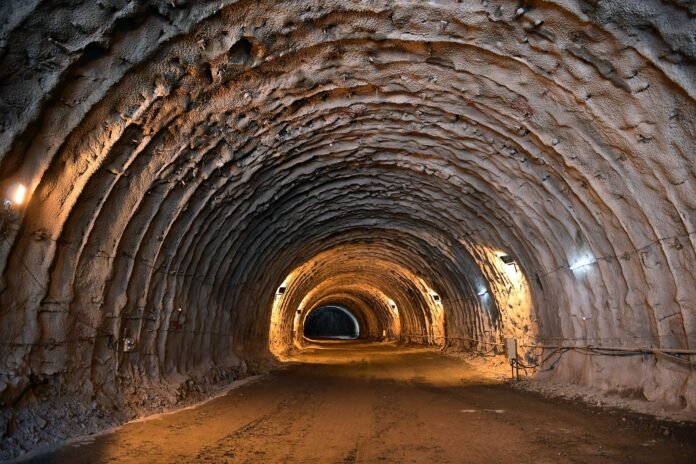

The 290 km-long USBRL project stands as one of the engineering marvels in the history of indian railway infrastructure. The project connects the valley of Kashmir with the rest of the country via a broad-gauge railway line which traverses through the Himalayas. The project faced several critical challenges due to the varying geology of the region.

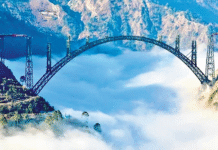

The project includes India’s longest tunnel, T49, between Sumber and Arpinchala station of the Katra-Banihal section of the USBRL project. T49 has a length of about 12.75km. The construction of this tunnel was carried out using the NATM. The region has primarily sedimentary rock composition, which poses challenges in the tunnel construction. However, the NATM empowered the engineers to proceed with excavation. Apart from T49, the other tunnels in the project are constructed using the same method. Recently, the inauguration of the Chenab Bridge, which is also the world’s highest railway bridge, marked the official completion of the project.

- Mumbai-Ahmedabad High Speed Rail Corridor:

India’s first high-speed rail corridor between Mumbai and Ahmedabad has witnessed steady progress in recent months. The project spans 508 km via 12 stations. In addition, the project integrates advanced tunnelling techniques across challenging terrain.

The corridor includes approximately 21 km of tunnelling, of which 16 km will be constructed using Tunnel Boring Machines (TBMs), while around 5 km will be executed using the New Austrian Tunnelling Method(NATM). One of the key milestones achieved so far is the excavation of a 394-meter-long, Additionally Driven Intermediate Tunnel (ADIT) at Ghansoli, which will provide access for NATM-based tunnelling activities.

This 26-meter-deep inclined ADIT enables simultaneous excavation in both directions, facilitating the construction of an approximately 3.3 km tunnel using NATM. The tunnel alignment includes a 7 km stretch passing beneath the Thane Creek’s intertidal zone, making it the first undersea tunnel of its kind in India for a high-speed rail system.

Conclusion

The New Austrian Tunnelling Method (NATM) has established itself as a reliable and adaptable tunnelling technique, particularly suitable for projects which involves complex or variable geological conditions. Its observational and flexible approach allows for real-time adjustments to support systems based on ground behaviour, which is especially valuable in regions with heterogeneous rock formations. The method’s systematic integration of monitoring, lightweight initial supports, and phased construction enables safe and efficient tunnel execution. As demonstrated in projects such as the USBRL and the Mumbai–Ahmedabad High-Speed Rail Corridor, NATM remains a practical solution in scenarios where mechanised methods like TBM may be limited by geological constraints.