Introduction

Rail transport is widely recognized as one of the most energy-efficient and cost-effective modes of transport. Over the past few decades, the sector has seen progressive developments in electrification, traction systems, and energy optimisation. A part of this transition has been the gradual replacement of diesel locomotives with electric traction to reduce dependence on fossil fuels. Despite this, only about one-third of the global railway network is electrified, while the majority continues to operate on diesel traction due to challenges such as high capital expenditure, operational feasibility in low-density corridors, and the technical complexities of installing overhead systems in difficult terrains.

Electrification, while an important initiative toward reducing emissions, does not on its own achieve carbon neutrality. This is because the electricity supply for railway operations in many regions is still derived from non-renewable sources such as coal, oil, and natural gas. Moreover, extending electrification across entire networks is not always economically justifiable, especially on regional, rural, or low-traffic lines where the cost-benefit ratio remains low.

To address these limitations, railways require propulsion technologies that are both operationally flexible and environmentally sustainable. Hydrogen fuel cell systems are gaining attention worldwide as a technically viable alternative in this context. Hydrogen fuel cells generate electricity through an electrochemical reaction between hydrogen and oxygen, which eliminates direct carbon emissions. The only by-product of this process is water vapor, which makes the system well-suited for decarbonising non-electrified rail corridors where conventional electrification is neither practical nor cost-effective.

The Need for Hydrogen-Powered Trains in Railways

The Indian Railways has set an ambitious target of achieving net-zero carbon emissions by 2030. In this context, hydrogen fuel cell technology can support Indian Railways in achieving its decarbonisation target while ensuring operational reliability and cost-effectiveness.. This paper examines the technical viability of integrating hydrogen fuel cell systems into existing rolling stock, while keeping the focus on their operational feasibility, energy efficiency, and lifecycle costs. The study also highlights the engineering challenges associated with such adoption, including hydrogen storage and refueling infrastructure, safety protocols, fuel cell durability under Indian operating conditions, and the compatibility of fuel cell systems with the current railway ecosystem.

The requirement for applying hydrogen fuel cell technology in Indian Railways arises from a combination of operational, environmental, and economic considerations. India has one of the largest railway networks in the world, with a significant portion still dependent on diesel traction. While electrification is progressing rapidly, hydrogen fuel cells can complement this effort by addressing specific challenges and gaps.

1. Large Dependence on Diesel Traction

Despite the ongoing electrification drive, Indian Railways continues to operate a sizable fleet of diesel locomotives, especially in non-electrified and remote sections. Hydrogen fuel cell trains offer a zero-emission alternative to diesel traction without the need for complete overhead electrification infrastructure, thereby saving on long-term electrification costs.

2. Net Zero Emission Targets

The Indian Railways has set the target of achieving net zero carbon emissions by 2030. Hydrogen-powered trains, producing only water vapor as a by-product, align directly with this goal by eliminating greenhouse gas emissions from non-electrified corridors.

3. Cost of Electrification vs. Green Alternatives

Electrification across the entire 68,000+ km route length is capital intensive and may not always be economically viable in sparsely used or geographically challenging routes (e.g., hilly terrain or low-traffic density lines). In such cases, hydrogen fuel cell technology provides a more practical and flexible solution compared to overhead wiring investments.

4. Renewable Energy Integration

India has ambitious renewable energy generation targets. Hydrogen produced through electrolysis using solar and wind power can serve as a sustainable energy carrier for railway applications. This allows Indian Railways to integrate surplus renewable energy into mobility, enhancing grid stability and energy security.

5. Reduction in Fuel Import Dependence

India is heavily dependent on crude oil imports to meet its diesel demand. Hydrogen as a fuel, if indigenously produced using renewable sources, reduces reliance on imported fossil fuels and enhances energy independence.

6. Technological Modernization of Rolling Stock

Hydrogen adoption promotes modernization of India’s rolling stock through hybrid propulsion systems (fuel cell + battery) and regenerative braking. This can reduce lifecycle maintenance compared to traditional diesel locomotives while improving efficiency.

7. Pilot Projects and Feasibility

Indian Railways has already announced pilot projects for hydrogen fuel cell trains on heritage and regional routes. These trials will serve as a test bed for wider adoption, helping to evaluate performance, hydrogen storage, refueling infrastructure, and cost-benefit ratios under Indian operating conditions.

8. Global Alignment and Competitiveness

Countries such as Germany, France, and China are already deploying hydrogen fuel cell trains. For Indian Railways, embracing this technology ensures alignment with international best practices and positions India as a potential hub for hydrogen-powered rail innovation.

In summary, the application of hydrogen fuel cell technology in Indian Railways is driven by the dual objective of decarbonization and operational efficiency. It serves as a critical alternative to full electrification, especially for remote and low-density routes, while contributing to India’s broader goals of sustainability, renewable energy utilization, and fuel import reduction.

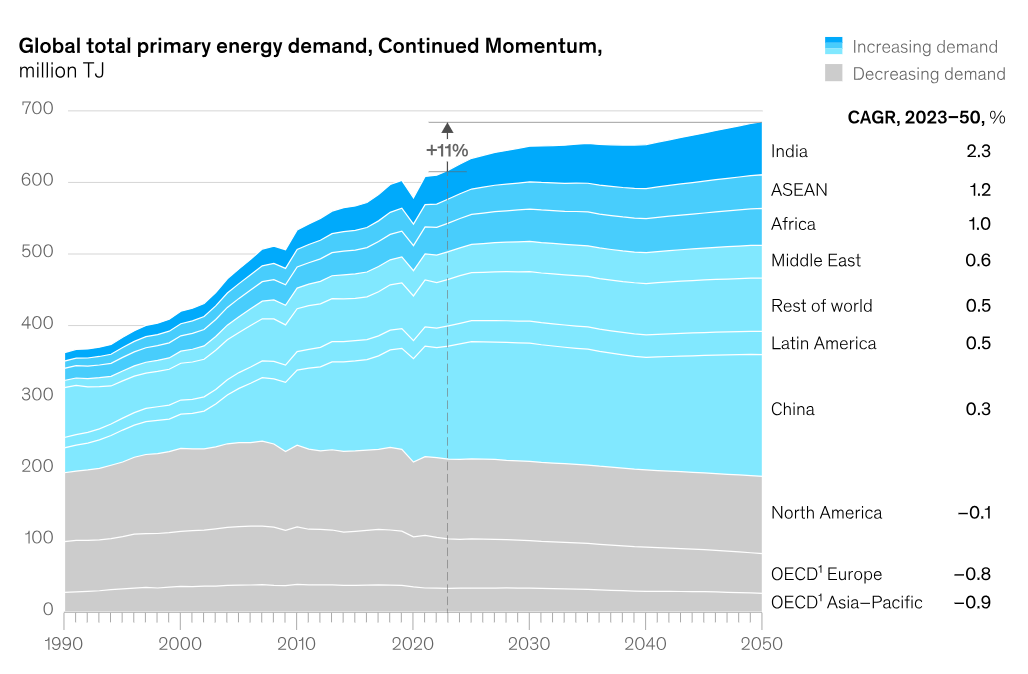

Rising Energy Demand: It is predicted that by 2050, the global energy demand will increase by almost 18%. In this scenario, green hydrogen offers a sustainable, renewable and versatile alternative to fossil fuels. This could help industries ranging from heavy manufacturing to transport by providing a cleaner path to meet their high energy requirements while reducing emissions.

Working Principle of Hydrogen Fuel Cells in Trains

Hydrogen fuel cells operate on the principle of an electrochemical reaction that directly converts the chemical energy stored in hydrogen into electrical energy, without the intermediate step of combustion.

In railway applications, the most widely used configuration is the Proton Exchange Membrane Fuel Cell (PEMFC) due to its relatively low operating temperature, quick start-up capability, and suitability for variable power demands encountered in train operations.

The process begins with hydrogen stored onboard the train in high-pressure tanks, typically at 350–700 bar. This hydrogen is supplied to the anode side of the fuel cell stack, where it undergoes catalytic dissociation. At the anode, each hydrogen molecule (H₂) splits into two protons (H⁺) and two electrons (e⁻). The protons migrate through the polymer electrolyte membrane, which is selectively permeable to protons but impermeable to electrons.

The electrons, unable to pass through the membrane, are forced to travel through an external circuit, generating a direct current (DC) that is used to power traction motors, auxiliary systems, or be routed into an onboard energy storage system. On the cathode side, oxygen drawn from the ambient air combines with the incoming protons and electrons to form water (H₂O), which is the only by-product of the reaction.

The overall electrochemical reaction can be expressed as:

Anode reaction: H₂ → 2H⁺ + 2e⁻

Cathode reaction: ½O₂ + 2H⁺ + 2e⁻ → H₂O

Net reaction: H₂ + ½O₂ → H₂O + Electrical Energy + Heat

The efficiency of a fuel cell stack typically ranges between 45–60%, which is considerably higher than the thermal efficiency of internal combustion engines (~30–35%). Additionally, the waste heat generated can be partially recovered for onboard heating systems, improving overall system efficiency.

In train applications, the fuel cell system is usually integrated with a hybrid architecture, where the fuel cell provides the base load power, while batteries or supercapacitors handle peak loads such as acceleration and regenerative braking. This hybrid configuration not only enhances energy efficiency but also prolongs the operational life of the fuel cell stack by avoiding high transient stresses.

The modular nature of fuel cell stacks allows scaling of power output to match the requirements of various rolling stock categories, ranging from light commuter trains to heavier regional trains. Depending on the design, a single trainset may house multiple stacks to deliver a combined output of several hundred kilowatts, sufficient for mainline operations on non-electrified routes.

The Framework Required for Implementation of Hydrogen Fuel Cell Technology in Indian Railways

The current railway ecosystem in India does not support the adoption of hydrogen fuel cell technology. Transitioning to this system will require not only a change in propulsion methods but also the development of a parallel ecosystem. This would include hydrogen production, distribution, and storage infrastructure, along with rolling stock adaptation, regulatory frameworks, and workforce skill development, to make the initiative both technically viable and economically sustainable.

Technological Adaptation of Rolling Stock

The existing diesel-electric rolling stock in India would need modifications to accommodate hydrogen fuel cell systems. This primarily involves the replacement of diesel engines with fuel cell stacks, coupled with the integration of hydrogen storage tanks, power electronics, and compatible electric traction systems. The Integral Coach Factory (ICF), Chennai, is currently retrofitting a Diesel Electric Multiple Unit (DEMU) train to operate on hydrogen fuel cell technology. This pilot project is expected to provide insights into the technical feasibility, operational safety, and cost-effectiveness of this technology.

Hydrogen Production and Supply Chain

Since hydrogen does not occur naturally in a usable form, establishing large-scale production facilities will be necessary for its application in Indian Railways. Currently, India does not produce hydrogen on a large scale for railway applications. Instead, it is gradually building capacity in this area, beginning with pilot projects. The country’s first hydrogen-powered train is planned to operate on the Jind–Sonepat route in Haryana, and will source hydrogen from a local 1 MW Green Hydrogen Electrolysis plant. The larger production and distribution networks are yet to be established in India.

Refueling and Storage Infrastructure

Hydrogen refueling depots that are specifically designed for railway applications will be necessary across the railway network, particularly on non-electrified routes. These facilities will be required to be equipped with high-capacity storage tanks, compressors, and dispensers that are capable of meeting the operational requirements of long-distance and high-frequency train services.

Safety and Regulatory Framework

The adoption of hydrogen fuel cell technology in railways will demand safety protocols. Hydrogen’s flammability and storage under high pressure create unique challenges that can only be encountered by setting up new regulatory standards for railway operations, storage systems, refueling procedures, and accident management.

Skill Development and Workforce Training

The present railway ecosystem in India is primarily oriented toward diesel and electric locomotives. The transition to hydrogen fuel cell systems will necessitate reskilling the workforce to manage new technologies and safety requirements.

Economic and Financial Considerations

The adoption of hydrogen fuel cell technology presents multiple benefits in the long term. However, the large-scale adoption of this technology in railways will require substantial costs related to rolling stock development, infrastructure deployment, and hydrogen production. For effective adoption, government subsidies, incentives, and public–private partnerships will be essential to reduce financial risks for both Indian Railways and industry stakeholders.

Research and Pilot Projects

Research and development institutions & pilot projects will play a crucial role in the large-scale implementation of hydrogen fuel cell technology across the railway network. They will help to understand the practical challenges of deploying hydrogen fuel cells in Indian conditions. The pilot projects can help assess energy efficiency, durability of components, climatic resilience, and lifecycle costs. Currently, one such pilot project is being implemented in India

The Ongoing Efforts: India’s First Hydrogen-Powered Train to Meet the Tracks Soon

The initiative to deploy hydrogen-powered trains originated from Indian Railways’ vision to reduce carbon emissions and promote sustainability in its operations. In 2021, Indian Railways issued a tender for a pilot project to convert a Diesel Electric Multiple Unit (DEMU) rake into a hydrogen-powered train. This pilot service is planned to operate on the Jind–Sonipat section of the Northern Railway. In the same year, the Research Designs and Standards Organisation (RDSO) finalised the design for India’s first hydrogen-powered train.

The Integral Coach Factory (ICF), Chennai, was assigned the task of manufacturing the train. This involved designing and producing coaches capable of carrying passengers while accommodating key components such as hydrogen cylinders, fuel cell converters, batteries, and air reservoirs.

In February 2023, Indian Railways announced its plan to operate 35 hydrogen trains under the ‘Hydrogen for Heritage’ initiative, which aims to reduce carbon emissions and encourage environmentally sustainable practices. This was confirmed by the Union Minister of Railways, Ashwini Vaishnaw, in a written reply to the Rajya Sabha in 2023.

To support this initiative, the Ministry of Railways allocated ₹2,800 crore in the Union Budget 2023–24 for the development of hydrogen-powered trains. The estimated cost of each train is around ₹80 crore, with an additional ₹70 crore required per route for supporting ground infrastructure.

Timeline of Key Developments in India’s Hydrogen Fuel Cell Train Project

- September 2022: Medha Servo Drives initiated procurement of hydrogen fuel cell modules for the DEMU retrofit pilot project. The order, placed with Ballard Power Systems, comprised eight 100 kW FCmove™-HD+ fuel cells.

- October 2023: GreenH Electrolysis (a joint venture between H2B2 Electrolysis Technologies and GR Promoter Group) entered into a contract with Medha Servo Drives to establish a hydrogen production and refuelling facility at Jind, Haryana.

- October 2024: GreenH Electrolysis announced the completion of a 1 MW PEM electrolyser at its manufacturing site in Jhajjar, Haryana. This unit is designated for installation at the Jind refuelling station to supply hydrogen for the pilot project. The electrolyser is designed to operate continuously, generating approximately 430 kg of hydrogen per day at a delivery pressure of 40 bar(g), and it meets ISO 14687 purity standards for fuel cell applications. The refueling facility at Jind will additionally incorporate 3,000 kg of hydrogen storage capacity, a hydrogen compressor, and two hydrogen dispensers with pre-cooler integration.

- July 2025 – Testing Phase Initiated: Indian Railways commenced the testing of its first hydrogen-powered coach, developed at the Integral Coach Factory (ICF), Chennai.

There are several challenges and safety considerations associated with the project, as hydrogen is a highly flammable gas. The pilot initiative involves retrofitting two diesel-powered cars into hydrogen fuel cell-powered units. Each power car is designed to carry approximately 220 kg of hydrogen, stored in specially engineered cylinders at 350 bar pressure. The design and testing of the cylinder mounting structures and fuel cell systems are critical to ensuring safety and reliability. Hydrogen, being the lightest element, is colourless, odourless, tasteless, and highly flammable. These inherent properties make rigorous safety protocols and multiple testing phases essential during its deployment in rail operations.

To minimise risks, Indian Railways has undertaken Computational Fluid Dynamics (CFD) studies to analyse potential worst-case scenarios of hydrogen leakage and other possible failure modes. The hydrogen-powered train will incorporate multiple layers of safety features such as pressure relief valves, hydrogen leak detection systems, flame detection sensors, temperature monitoring systems, and scientifically designed ventilation arrangements. These measures aim to ensure operational safety and system reliability during deployment. An independent third-party safety audit is being conducted by Technischer Überwachungsverein Süd (TÜV-SÜD), Germany, to validate and ensure compliance with international safety standards.

Global Developments in Hydrogen-Powered Trains

Germany – Alstom Coradia iLint

Germany became the first country to deploy hydrogen-powered trains for passenger service. Alstom’s Coradia iLint, introduced in 2018, operates commercially in Lower Saxony. The train offers a range of nearly 1,000 kilometers on a single hydrogen fill which proves it suitable for regional routes without electrified tracks.

France – SNCF Hydrogen Regional Train: France is progressing with hydrogen adoption through SNCF, which has placed orders for regional multiple units that will be powered by hydrogen fuel cells. These trains are designed to replace diesel units on non-electrified lines and form part of France’s broader commitment to reduce emissions in regional mobility.

United Kingdom – HydroFLEX Project

The UK has focused on retrofitting existing rolling stock for hydrogen trials. The HydroFLEX project converted a Class 319 electric multiple unit into a hybrid hydrogen-powered train. It serves as a demonstrator for future large-scale applications.

Japan – Hybari Prototype

The Hybari prototype is Japan’s first hydrogen-powered test train. It was developed by East Japan Railway (JR East) in collaboration with Toyota and Hitachi. The prototype has an operational speed of up to 100 km/h and a range of about 140 km per hydrogen charge. While the prototype has been successful in its testing phase, JR East’s target for commercial application of the technology is still set for around 2030.

China – Hydrogen Trams in Qingdao

China has deployed hydrogen-powered trams in Qingdao since 2015, making it one of the earliest large-scale applications of hydrogen in rail transit. These trams demonstrate the feasibility of hydrogen technology in urban public transport and reflect China’s push toward cleaner mobility solutions.

World’s First Hydrogen-Powered Semi-High Speed Train

CRRC is planning to launch the world’s first hydrogen-powered semi-high-speed train. The prototype is capable of reaching the speed of 250kmph and will be ready by the end of 2025.

United States – Stadler FLIRT H2

In the United States, Stadler is developing the FLIRT H2 trainset for California. The commercial rollout of this hybrid train is expected by 2027. The project aims to provide a zero-emission alternative for regional rail corridors.

During its testing period, the FLIRT H2 made a Guinness World Record for the longest distance covered by a hydrogen-powered train without refueling.

Distance: 2,803 kilometers (1,741.7 miles).

Max. Speed: 130 km/h (79 mph).

Duration: 46 hours on a single tank at a test track in Pueblo, Colorado.

Technical Challenges and Limitations

Despite the promise, hydrogen technology faces significant challenges. At present, most hydrogen is produced from natural gas, known as “grey hydrogen,” which releases carbon dioxide in the process. Sustainable alternatives, such as “green hydrogen” produced via electrolysis powered by renewable energy, remain expensive, with current costs ranging from four to six dollars per kilogram. Storage and transport pose another challenge, as hydrogen has a low volumetric energy density and requires high-pressure tanks or liquefaction facilities.

From a financial perspective, the capital cost of a hydrogen train is 30 to 50 percent higher than a comparable diesel unit, while fuel cell stacks degrade over time, with a typical operating lifespan of 20,000 to 30,000 hours. Moreover, in high-density corridors, electrification still remains more efficient, creating competition for hydrogen adoption.

Future Outlook

Global trends suggest that the cost of green hydrogen will fall sharply in the coming decade, potentially reaching one to two dollars per kilogram by 2030 as electrolyzer technology advances and renewable energy capacity increases. Hybrid hydrogen-battery systems are also under development to optimize performance and reduce hydrogen consumption. For large-scale deployment, India will need to establish hydrogen corridors with dedicated refueling infrastructure. Policy support, public-private partnerships, and integration with renewable energy projects will be critical in this transition.

Conclusion

Hydrogen fuel cells represent a transformative opportunity for railways, providing a clean, quiet, and efficient alternative to diesel on non-electrified routes. Their technical merits include zero tailpipe emissions, long operating range, and fast refueling capabilities, though they remain constrained by high costs and infrastructure requirements. For India, hydrogen trains could serve as a bridge technology, supporting decarbonization goals while reducing reliance on imported fossil fuels. As global case studies demonstrate, the continued advancement of hydrogen technology, coupled with the scaling of green hydrogen production, has the potential to reshape rail mobility and contribute meaningfully to a carbon-neutral future.