Introduction

The demand for faster, safer, and more sustainable modes of transportation is influencing the global mobility landscape. As metropolitan regions continue to expand and populations surge, existing transport systems are struggling to keep pace with the growing need for efficiency, reliability, and reduced travel times. Railways, traditionally known for their ability to move large volumes of passengers and freight, have undergone an evolution over the decades. The introduction of high-speed rail, often referred to as bullet trains, has improved intercity travel by drastically minimising the journey times and offering a viable alternative to air transport on many routes.

Despite their success, conventional high-speed rail faces inherent limitations. Factors such as wheel–rail friction, aerodynamic drag, and energy consumption restrict trains from surpassing certain speed thresholds efficiently. To overcome these barriers and push the boundaries of rail transport, engineers and innovators have turned to futuristic alternatives such as magnetic levitation (Maglev) and Hyperloop systems. Both technologies represent a paradigm shift in high-speed travel. Maglev trains operate by eliminating physical contact between the train and the track through electromagnetic suspension, thereby reducing friction and enabling speeds far beyond those of conventional rail. Hyperloop, on the other hand, envisions passenger pods travelling through near-vacuum tubes at supersonic velocities. While Maglev technology is already operational in countries like Japan and China, the Hyperloop remains largely in the experimental and developmental phase, with various prototypes and pilot projects being tested across the world.

Together, these emerging technologies are creating a new era in high-speed transportation. This study aims to explore the evolution of high-speed rail beyond conventional bullet trains, with a particular focus on Maglev and Hyperloop systems. It will examine their technological principles, potential advantages, and challenges in large-scale implementation.

A Journey Through Time: Tracing the History of High-Speed Rails

Speed has always been a defining parameter in the modernisation of rail transportation. Over time, the pursuit of reduced travel times has driven the transition from conventional rail to dedicated high-speed systems. The International Union of Railways (UIC) defines high-speed rail as services operating at commercial speeds of 250 km/h or more on purpose-built infrastructure.

However, the UIC also recognises a secondary operational threshold in specific corridors where competition with air travel is minimal or where geographical and demand conditions make extreme velocity unnecessary. In such cases, sustained speeds between 220–230 km/h, or at a minimum above 200 km/h, are considered sufficient to ensure a modal shift from conventional rail and road transport, while maintaining operational efficiency and economic viability.

Early Planning and Experiments

Germany (1899–1903)

The pursuit of higher rail speeds can be traced back to Germany at the end of the 19th century. Between 1899 and 1903, the Prussian State Railway, in collaboration with ten electrical and engineering firms, electrified a 72 km stretch of track between Marienfelde and Zossen for experimental purposes. These trials were the first systematic effort toward high-speed rail. By 1903, experimental electric railcars reached a maximum speed of 210.2 km/h. However, these trains were confined to testing and never entered regular passenger service.

Diesel-Electric Advancements in Germany (1930s)

DRG Class SVT 877 Hamburg Flyer 1932

The introduction of the DRG Class SVT 877 Hamburg Flyer (Fliegender Hamburger) in 1933 was another achievement in regular high-speed service. This diesel-powered train operated between Hamburg and Berlin at a top commercial speed of 160 km/h. Three years later, in 1936, the steam-powered Henschel-Wegmann Train also entered service with similar performance parameters. Although the outbreak of the Second World War curtailed further advancements.

Early Developments in the United States (1930s)

Parallel to German efforts, the United States also made progress in high-speed rail technology during the 1930s. The Zephyr, introduced in 1934, demonstrated operational speeds of 124 km/h, with test runs reaching up to 185 km/h.

United Kingdom 1938: Breaking world speed record for steam locomotives

In 1938, the United Kingdom established a speed benchmark for steam-powered locomotion. The locomotive “Mallard” achieved a world-record speed of 202.58 km/h on 3rd July 1938. Although the achievement was largely symbolic, it highlighted the maximum potential of steam technology before the widespread transition to diesel and electric propulsion systems.

First Bullet Train Enters Commercial Operations: 1964

While many countries were still experimenting with higher-speed rail systems, Japan took the decisive step of launching the world’s first high-speed rail service. On 1 October 1964, the Shinkansen, popularly known as the “bullet train,” began operations between Tokyo and Osaka. The initiative was approved by the Japanese Diet in March 1959, with a clear timeline: completion before the 1964 Tokyo Olympic Games. This ambitious schedule gave the project less than five years for design, construction, and commissioning. The target speed was over 210 km/h (131 mph).

Japan’s success with the Shinkansen in 1964 became the beginning of global high-speed rail development. Inspired by this model, several countries in Europe and Asia initiated their own high-speed rail systems in the following decades. A major milestone was reached in 1990, when France introduced the TGV Atlantique, the first high-speed train to operate commercially at 300 km/h (186 mph). The service was launched on the Paris–Le Mans and Paris–Tours sections of the LGV Atlantique line, which set a new benchmark for operational speed in passenger rail transport.

Current Developments in Bullet Train

At present, China’s Fuxing Hao CR400 is the fastest conventional bullet train in the world. The train is certified for a design speed of 400 km/h (249 mph), while its regular operational speed is capped at 350 km/h (217 mph) to ensure safety, energy efficiency, and long-term reliability of track and rolling stock components.

India’s Drive for High Speed Rail Operations

India, currently the world’s fourth-largest economy, has set its sights on attaining developed nation status by 2047. Achieving this goal requires advancements in infrastructure, where transportation plays a critical role. India’s first high-speed rail corridor, spanning about 508 km, is currently being developed between Mumbai and Ahmedabad, a major commercial hub of the country. By 2026, bullet trains are expected to begin operations on the initial section of this corridor.

The Beginning of the Maglev Era: A Leap in High Speed Rail

Despite achieving higher speeds, conventional bullet trains faced inherent limitations that restricted further advancements. The reliance on wheel-to-rail contact introduced friction, wear and tear, and noise at high speeds, which makes sustained operations above 350–400 km/h less efficient. Additionally, aerodynamic resistance increased as trains approached higher velocities, which further constrained performance. These factors collectively encouraged the transition towards magnetic levitation (maglev) technology, which eliminates wheel-rail friction, reduces noise, and allows trains to operate at much higher speeds while providing efficiency, safety and passenger comfort.

Evolution of Maglev Technology: A Track from Blueprint to Reality

Robert Goddard (1904): Robert Goddard was an American professor who wrote a paper on a frictionless system that would use electromagnetic repulsion to raise a train from its track in 1904.

Emile Bachelet (1914): In 1914, French-born American inventor Emile Bachelet introduced the concept of a magnetically levitated vehicle and demonstrated it with a working model

Hermann Kemper 1922: German engineer Hermann Kemper began systematic research on magnetic levitation in 1922. By 1933, he constructed a working circuit that demonstrated hovering based on electromagnetic attraction. His efforts culminated in 1937, when he was granted a German patent for a magnetic levitation train powered by linear motors.

1962: Japan began research on a linear motor propulsion magnetically levitated railway system in 1962

1969: Building upon the theory of Kemper, the German government sponsored the first full-scale maglev model, the Transrapid TR01

1970s: Japan developed superconducting magnet-based electrodynamic suspension (EDS) systems and began test runs.

1979 – The Transrapid 05 became the first passenger-carrying maglev, showcased at the International Transportation Exhibition in Hamburg (Germany).

1984 – The Birmingham Maglev became the world’s first commercial maglev train. It was a slow-speed (up to 42 km/h / 26 mph), short-length (600 m / 2,000 ft) shuttle between the Birmingham Airport and the Birmingham International railway station.

1991: A 42.8 km maglev test track was built in Yamanashi Prefecture to advance EDS-based technology.

1997(Germany): The Transrapid 07 achieved over 450 km/h on the Emsland test track.

2004: The Shanghai Maglev Train (SMT), also known as Shanghai Transrapid, began commercial service in China.

2005: Japan’s first commercial maglev, the Linimo (Tobu Kyuryo Line), opened for the 2005 World Expo in Aichi.

2015: Japan Railway Central’s L0 Series maglev sets a world record speed of 603 km/h on the Yamanashi Test Track.

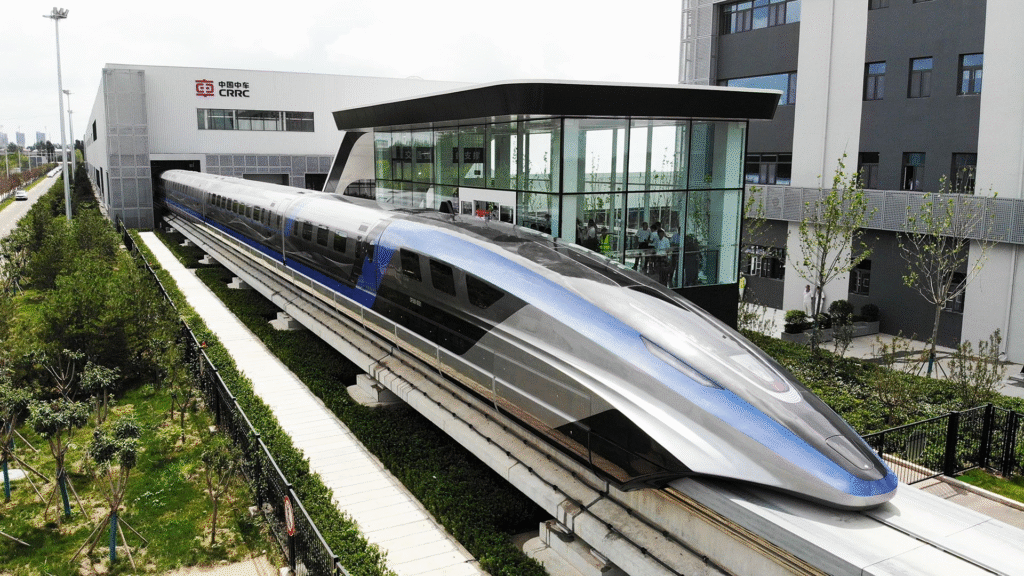

2021: CRRC Qingdao Sifang unveiled a prototype maglev train capable of 600 km/h, which is the fastest ground vehicle developed in China.

2025: China reported a new world speed record where a maglev train prototype reached the top speed of 650 km/h.

The Principle of Maglev Technology

Maglev (Magnetic Levitation) technology is based on the principle of using magnetic forces to lift, propel, and guide a vehicle instead of relying on wheels, axles, and bearings. The system eliminates physical contact between the train and the track, which minimises the friction and allows for higher speeds and smoother rides.

The principle of maglev technology rests on three main concepts:

- Magnetic Levitation: The train is equipped with strong magnets which lift the train above the guideway. This removes rolling resistance, as there are no wheels in contact with the track.

- Magnetic Propulsion: For moving the trains, Linear motors (Linear Induction Motor or Linear Synchronous Motor) are employed, which generate a moving magnetic field. This magnetic field pulls and pushes the train forward along the guideway.

- Magnetic Guidance: The same magnetic forces are used to keep the train aligned laterally and prevent it from drifting sideways. This becomes possible with the help of sensors and control systems, which constantly adjust the magnetic field to ensure stability and safety.

Types of Maglev Systems: There are two types of Maglev trains, electrodynamics suspension trains (EDS) and electromagnetic suspension trains(EMS).

Electromagnetic Suspension trains

Electromagnetic Suspension (EMS) technology relies on the principle of magnetic attraction to achieve levitation. In this system, powerful electromagnets are installed on the underside of the train, which partially wrap around the guideway. The guideway itself contains a complementary arrangement of magnets with opposite polarities. The attraction generated between these two sets of magnets is carefully controlled so that it counterbalances the train’s weight, creating a stable lift. This allows the train to hover at a distance of around 1.3 centimetres above the guideway, while an additional clearance of 8–10 centimetres is maintained between the lower body of the train and the underside of the track. One of the distinct advantages of EMS is its ability to sustain levitation even when the train is at rest.

The train movement is facilitated using linear motors, where alternating magnetic fields embedded in the guideway interact with the propulsion system housed on the train. This arrangement eliminates the need for traditional wheels, axles, or rails.

Germany has been at the edge of EMS research and development. Transrapid International (TRI), a collaborative initiative between Siemens AG and ThyssenKrupp, began systematic studies of electromagnetic levitation in 1969. That same year, they produced the first prototype of an EMS vehicle. Over subsequent decades, eight successive generations of EMS trainees were developed. The culmination of this research was realised when the final two generations entered commercial service in Shanghai in January 2001.

Electrodynamic Suspension (EDS) trains

In contrast to Electromagnetic Suspension (EMS), which relies on magnetic attraction, Electrodynamic Suspension (EDS) trains use the principle of magnetic repulsion to counteract Earth’s gravitational pull. This system makes extensive use of superconductors, which are special materials that conduct electricity with zero resistance when cooled below a certain threshold known as the critical temperature. Once an electric current is induced in a superconductor, it can circulate indefinitely without energy loss, even for years. They can generate extremely powerful magnetic fields and withstand forces thousands of times greater than their own weight.

In EDS trains, superconducting magnets mounted on the vehicle interact with conductive coils arranged along the guideway. When the train moves, the changing magnetic fields induce currents in the guideway coils, creating opposing magnetic fields. The interaction produces a repulsive force that lifts the train above the track, allowing it to levitate. Unlike EMS systems, EDS maglev trains are equipped with retractable wheels that support the vehicle at low speeds and are withdrawn once the train reaches the critical speed required for stable levitation. The EDS Maglev can not levitate in the standing position.

Propulsion in EDS systems is achieved using a configuration similar to linear motors but inverted. The guideway is lined with sequential coils which carry alternating currents. By carefully switching the polarity of these coils, a moving magnetic wave is created along the track. The superconducting magnets on the train are repelled by the coils behind them and attracted to the coils ahead, pulling the train forward. As the coils continuously change polarity in synchronisation with the train’s position, this cycle repeats. The faster the switching frequency, the faster the train travels.

Japan has established itself as a global leader in developing EDS-based maglev technology. It has carried out extensive testing on the Yamanashi Maglev Line, where trains have achieved record-breaking speeds exceeding 600 km/h.

Maglev in Operations

At present, Maglev trains are operating in 3 countries.

Japan

In Japan, the Linimo line in Aichi was built for the 2005 World Expo and remains in operation today. The line covers 9 km, has nine stations, and runs at speeds of up to 100 km/h.

In addition, the SCMaglev (Superconducting Maglev) is currently under construction for the Chūō Shinkansen line between Tokyo and Nagoya. The trains on the new route are expected to operate at speeds exceeding 600 kmph.

South Korea

South Korea operates two commercial maglev systems. The first is the Korean Rotem Maglev in Daejeon, which opened in 1993 and covers a 1 km stretch between the Expo Park and the National Science Museum. The second is the Incheon Airport Maglev which was inaugurated in 2016. It covers 6.1 km via six stations between Incheon International Airport and Yongyu Station.

China

China has three maglev systems in operation. The Shanghai Maglev, opened in 2003, is the world’s first high-speed commercial maglev line. It runs for 30 km between downtown Shanghai and Pudong International Airport, with trains reaching speeds up to 430 km/h.

The Changsha Maglev was launched in 2016. It connects Changsha Huanghua International Airport to the South Railway Station over an 18.5 km route at a speed of 100 km/h.

The third system is the Beijing Subway S1 Line, which was opened in 2017. It spans 9 km with seven stations and operates at 100 km/h as part of the city’s metro network.

China Sets New Maglev Speed Record

China reported a new world speed record for a maglev train after a prototype reached 650 km/h during a trial. The test was conducted on June 17 2025, at the Donghu Laboratory High-Speed Magnetic Levitation Electromagnetic Propulsion Technology Innovation Centre in Hubei province.

The Obstacles in Bringing Maglev into the Mainstream

Cost Concerns over Innovative Rail:

The single biggest obstacle for maglev technology is the need for a completely new infrastructure. The cost per kilometre of maglev construction (estimated at USD 50–120 million) is higher than conventional HSR. Maglev trains cannot run on existing conventional rail tracks, which means new, dedicated guideways must be built for the entire route. This makes initial construction costs astronomically high compared to upgrading existing rail lines.

Non-Interoperability with Conventional Rail:

Unlike high-speed rail (HSR), maglev vehicles are not compatible with steel-wheel tracks. This lack of interoperability prevents integration into existing railway corridors.

Energy and Power Demand

Although rolling resistance is eliminated in Maglev trains, but high-speed maglev systems exhibit high aerodynamic drag at velocities above 400 km/h. In electrodynamic suspension (EDS) systems, cryogenic refrigeration is required to maintain superconductivity, which adds to the base-load power demand. In this situation, sustaining propulsion at ultra-high speeds (≥ 500 km/h) requires continuous high-capacity power supply infrastructure.

Complexity of Electromagnetic Systems & Technological Gaps

Both Electromagnetic Suspension (EMS) and Electrodynamic Suspension (EDS) technologies require highly sophisticated electromagnetic control systems to ensure safe levitation, stability, and propulsion. The integration of these systems demands extensive research and development (R&D) in advanced materials, superconducting technology, and real-time control algorithms. Furthermore, their deployment necessitates a specialized and highly skilled workforce trained in areas such as power electronics, high-frequency control systems, and cryogenic engineering expertise that is not yet widely available within the existing conventional railway ecosystem. This gap in technical competency acts as a major barrier to mainstream adoption.

Evacuated Tube Transport & Hyperloop Systems

The demand for high-speed transportation will continue to grow as urbanization intensifies and cities evolve into megacities. In such environments, the efficiency of supply chains will remain critical to sustaining urban life and economic activity. However, conventional transportation systems are constrained by physical and technological speed barriers, which limit their ability to meet future requirements. The emerging concepts such as Evacuated Tube Transport (ETT) and Hyperloop present potential solutions by offering ultra-high-speed, energy-efficient, and sustainable transit systems which are designed to overcome these limitations.

Evacuated Tube Transport (ETT)

The origins of Evacuated Tube Transport (ETT) can be traced to the early 20th century, when Dr. Robert Hutchings Goddard proposed the concept of a vactrain. His idea involved a magnetically levitated vehicle operating within a vacuum-sealed tube, aimed at reducing aerodynamic drag to enable higher travel speeds.

The concept was later developed further by Daryl Oster, founder of ET3, who received a patent for ETT. Theoretically, such a system could achieve speeds in the range of 6,000–7,000 km/h under controlled conditions.

In practice, implementation faces major constraints. Constructing and maintaining long-distance vacuum tubes requires substantial capital investment, precision engineering, and advanced material technology to ensure structural integrity and energy efficiency. Additionally, safety systems for passenger operations in such an environment remain underexplored. For these reasons, ETT has not advanced beyond the conceptual stage. Although continued progress in relevant technologies may enable more applied research in the future.

The Era of Hyperloop: A Practical Approach for High Speed Transportation

On August 12, 2013, Elon Musk, then serving as the CEO of Tesla and SpaceX, released the Hyperloop Alpha white paper. The document outlined a conceptual design for a high-speed transportation system that would use low-pressure tubes and pod-like vehicles to achieve speeds exceeding 1,000 km/h. The proposed system combines principles of magnetic levitation (Maglev) with near-vacuum conditions to minimise aerodynamic drag and rolling resistance.

The foundational principles of the Hyperloop system bear a strong resemblance to the earlier concept of Evacuated Tube Transport (ETT). However, a crucial distinction lies in their operational environments: while ETT envisions capsules moving through tubes maintained at a complete vacuum, the Hyperloop proposes travel within low-pressure tubes. This approach avoids the technical and financial challenges of maintaining a perfect vacuum over long distances while still minimising aerodynamic drag.

The white papers state, much like how aircraft ascend to high altitudes to fly through thinner air, the Hyperloop concept encloses capsules in a tube where air pressure is drastically reduced. Specifically, the operating pressure of the Hyperloop is proposed to be around 100 Pascals, which is approximately 1/6th the atmospheric pressure on Mars. Under these conditions, the drag force on a moving pod would be reduced by nearly 1,000 times compared to sea-level conditions, creating an effect equivalent to travelling at an altitude of over 150,000 feet.

Global Initiatives for the Development of Hyperloop Systems

Hyperloop technology is still in its developmental stage, and currently, multiple companies and research institutions worldwide are working to translate the concept into a commercially viable transportation system.

Virgin Hyperloop (formerly Hyperloop One): Virgin Hyperloop, established in 2014, constructed a test facility in Nevada, USA, where it conducted the first full-scale Hyperloop test in May 2017. In November 2020, the company performed the first human passenger trial, where the pod reached approximately 160 km/h. Although this was a significant step, it remained well below the projected speeds of over 1,000 km/h.

In 2022, Virgin Hyperloop shifted its focus from passenger transport to freight systems due to regulatory, financial, and technical challenges. By 2023, reports confirmed that the company had closed operations and sold its assets.

Other Global Efforts:

In addition to Virgin Hyperloop, several other companies and organisations are actively exploring hyperloop systems:

TuTr Hyperloop (India): A startup from the Indian Institute of Technology Madras (IIT Madras), TuTr Hyperloop, has entered into partnerships with international companies and is developing a freight-focused hyperloop system.

Hardt Hyperloop (Netherlands): Hardt Hyperloop was founded in 2016 and operates from Delft, Netherlands. It has developed a test facility and focuses on key technologies such as lane-switching mechanisms, which allow pods to change tracks within the tube.

TransPod (Canada): TransPod, headquartered in Toronto, is developing the “FluxJet,” a pod system based on Hyperloop principles.

Current Status: While these initiatives highlight a strong global interest, hyperloop technology still faces engineering, financial, and regulatory challenges. Issues such as vacuum maintenance over long distances, passenger safety in emergencies, land acquisition, and infrastructure costs remain major hurdles. As of now, no commercial hyperloop system is operational.

Conclusion

Maglev and Hyperloop technologies show very potential in high-speed ground transportation. Urban-scale applications of Maglev, including Japan’s Linimo and South Korea’s Incheon Airport Maglev, have shown the practicality of medium and low-speed systems in improving travel time, passenger comfort, and reducing environmental impacts. At the same time, high-speed test lines, such as the Yamanashi Maglev in Japan, demonstrate the potential for intercity connections at higher speeds. The concept of the Hyperloop builds on Maglev technology by combining it with low-pressure tube environments to minimise aerodynamic drag. Despite its potential, Hyperloop systems and Maglev face major technical, financial and regulatory challenges. Further research and phased implementation are necessary to determine the long-term feasibility of both Maglev and Hyperloop. If successfully developed, these technologies could serve as complementary or alternative solutions to conventional high-speed rail.

Wow this article was amazing . It gave my mind a fresh thought abt the technological advancements made on basis of need and necessity. And it’s wonderful how human’s always evolve and find a way through these evolving demand.. I wish to get more updates and can I get suggestions regarding these technologies or books regarding this topic so I can make research in my ability.

இது போன்ற நல்ல கருத்துக்களை பகிர்ந்ததர்க்கு மிக்க நன்றி.ஒரு சிறிய கதை சொல்கிறேன் முன் காலத்தில் இடையன் பால் சுமந்து வருவதற்கு ஒரு கலைக்குச்சியில் பால்குடம் ஒரு பக்கம் அதை பேலன்ஸ் பண்ண கல்லை கட்டிக் கொள்வது வழக்கம் இப்போதும் வந்தே பாரத் ரயிலில் வரும்பொழுது அதே பீலிங் ஆகிறது. 250 பேர் பயணம் செய்யும் விமானத்தின் வெயிட்டும்,78 பேர் பயணம் செய்யும் ரயில் கோச்சின் வெயிட்டை விட மூன்று மடங்கு கம்மி. எப்பத்தான் வீல் AND ஆக்சில் டெக்னாலஜியை விடுவார்கள் என்று தெரியவில்லை மாட்டு வண்டியில் இருந்து குதிரை வண்டி, சாரட் வண்டி,ஒவ் ஒரு மாற்றத்துக்கும் வேகம் அதிகம் ஆகி உள்ளது,பெங்களூரில் இருந்து சென்னை செல்வதற்கு வால்வோ பஸ் (4 1/2 )ஹவர்ஸ் எடுத்துக் கொள்கிறது.கம்பி மேலே செல்லக்கூடிய அதிவேக ரயில் 51/2மணி நேரம் எடுக்கிறது அதனால் ஏதோ பெரிய தவறு செய்கின்றோம் இதற்கு என்னிடம் பரிகாரமும் இருக்கிறது.