Introduction

Braking systems form one of the most critical subsystems in railway engineering. They directly influence the safety, reliability, and operational efficiency of train operations. The ability to control train speed and ensure a predictable stop within a defined braking distance is fundamental for both passenger and freight operations. As the demand grows for high-speed train operations, traditional braking methods such as vacuum and conventional pneumatic brakes have proven inadequate in meeting modern performance and safety requirements.

Modern rail vehicles now rely on advanced braking technologies that combine mechanical, pneumatic, and electrical principles to deliver better responsiveness, energy efficiency, and fail-safe operations. These systems not only reduce stopping distances but also integrate with train control and protection mechanisms, such as Automatic Train Protection (ATP) and India’s indigenous Kavach system, to prevent accidents arising from human error or equipment failure.

Additionally, energy recovery through regenerative braking, widespread adoption of disc-based systems, and the use of contactless braking solutions such as eddy current and magnetic track brakes have converted braking into a multi-functional system that ensure safety while contributing to sustainability.

This paper explores the critical role of modern braking systems in enhancing the safety, efficiency, and reliability of rail transit operations. As metro rail, high-speed rail, and suburban transit systems expand globally, the demand for advanced braking technologies is increasing proportionally. Modern brakes are no longer limited to mechanical stopping functions, as they now incorporate regenerative energy recovery and electronic control. They are aligning with the industry’s push for efficiency and sustainability.

Along with technical improvements, the development of modern braking systems is also creating business opportunities for manufacturers. Investments in new metro and high-speed rail projects, the replacement of older rolling stock, and the enforcement of stricter safety standards are increasing the demand for reliable and efficient braking solutions. This paper looks at both the technical side of braking systems and the market potential.

Evolution of Railway Braking Systems

The development of railway braking technology has been closely linked to the increase in train speeds, axle loads, and passenger safety requirements over the last century. Early railways primarily relied on hand-operated mechanical brakes, which were applied by guards or brakemen stationed in individual wagons. This system was highly inefficient, inconsistent, and unsafe, particularly for long freight trains.

To overcome the limitations of mechanical brakes, vacuum brakes were introduced in the mid-1860s. Vacuum brakes, while simpler in construction, suffered from limited braking force and slower response times, especially on long rakes. Their performance under adverse weather conditions and at higher speeds also created challenges.

The invention of the compressed air brake by George Westinghouse between 1869 and 1872, turned out to be a major technological leap. Pneumatic air brakes allowed for simultaneous braking across the entire train. This reduced stopping distances and improved safety. Over time, this system evolved into electro-pneumatic (E-P) brakes, which use electrical signals for faster actuation and more uniform brake application.

As the modern rolling stock entered operations, further innovations were introduced. Disc brakes provided superior performance compared to tread brakes, especially at higher speeds, while regenerative and rheostatic braking systems enabled energy recovery and reduced wear on mechanical components. In parallel, contactless technologies such as eddy current and magnetic track brakes were developed to provide additional emergency braking capacity, particularly for high-speed rail applications.

This gradual progression from manual to highly automated, multi-modal braking systems reflects the increasing emphasis on reliability, safety, and efficiency in modern railway operations.

Types of Modern Brake Systems

Modern rail vehicles employ a combination of mechanical, pneumatic, and electrical braking technologies to meet the demands of higher speeds, improved safety, and operational efficiency. The main systems in use today include:

- Electro-Pneumatic Brakes

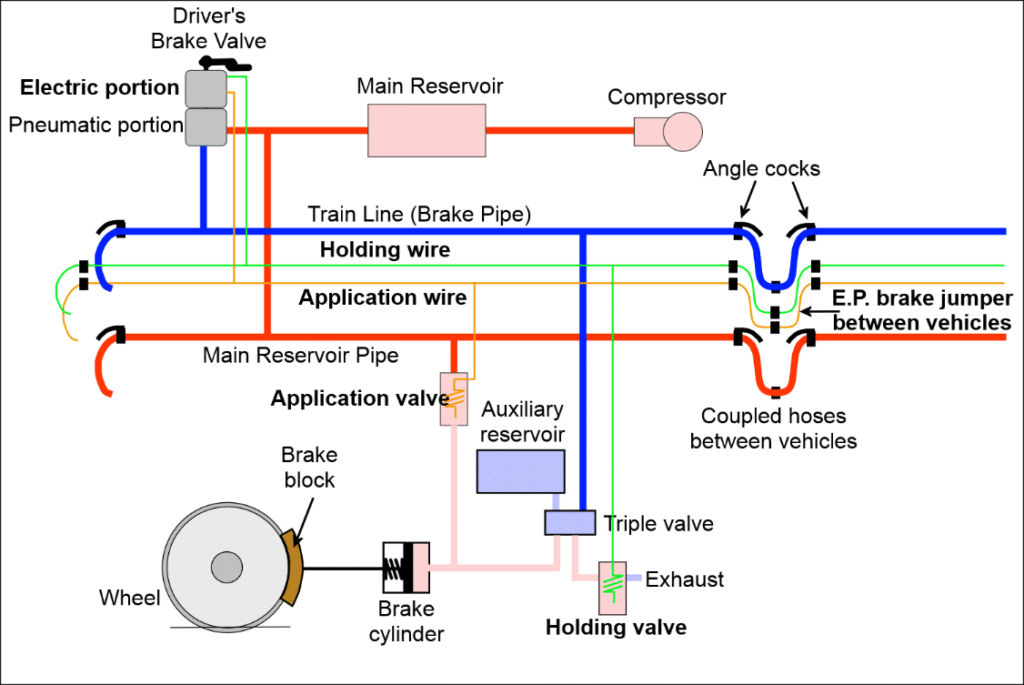

Electro-pneumatic (E-P) brakes are an improved form of the conventional air brake. They were first used in the United States on the New York Subway in 1909 and later on the London Underground in 1916.

In this system, the main braking power still comes from compressed air acting on the brake cylinders, but the control of the brakes is done electrically. Instead of relying on air pressure changes to travel through the brake pipe, electrical signals are sent along the train. These signals reach electro-pneumatic valves on each vehicle, which then allow compressed air from the reservoirs to enter the brake cylinders. This makes the brakes apply and release almost instantly and at the same time across the whole train.

E-P brakes are mainly used in multiple-unit passenger trains and metro systems, where quick and reliable braking is required. Their main benefit is faster response compared to conventional air brakes, which improves train handling, reduces stopping distance, and allows closer train spacing. The system is also suitable for use with automatic train operation (ATO) and train protection systems.

For safety, the conventional pneumatic brake system is usually kept as a backup. If the electrical control fails, the air brake still works to bring the train to a stop in an emergency situation.

- Regenerative and Rheostatic Braking

Modern rail systems increasingly rely on energy-efficient braking technologies that not only slow the train but also recover or dissipate energy. Regenerative braking captures the kinetic energy of a moving train and converts it into electrical energy, which can be fed back into the power supply system or reused.

Working Principle: During braking, the train’s traction motors operate as generators. The kinetic energy of the train is converted into electrical energy, which flows back into the traction power network if the infrastructure allows. If the network cannot absorb all the generated energy, it is dissipated as heat through rheostatic braking, where resistors onboard the train convert the energy into thermal energy. Rheostatic braking ensures that braking remains effective even when regeneration is not possible, such as during low power demand or network faults.

Many metro systems, including the Delhi Metro, Kolkata Metro, Pune Metro (Metro Line 3), and Indore Metro, utilise regenerative braking technology to convert the train’s kinetic energy into electricity.

- Disc Brakes

As the speed of rail transportation increased with technological progress, the demands on braking systems also grew. Higher speeds mean greater kinetic energy, which must be converted into heat during braking. Traditional block (or tread) brakes, which press brake blocks directly against the wheel tread, were adequate for lower speeds but became less effective as trains got faster and heavier.

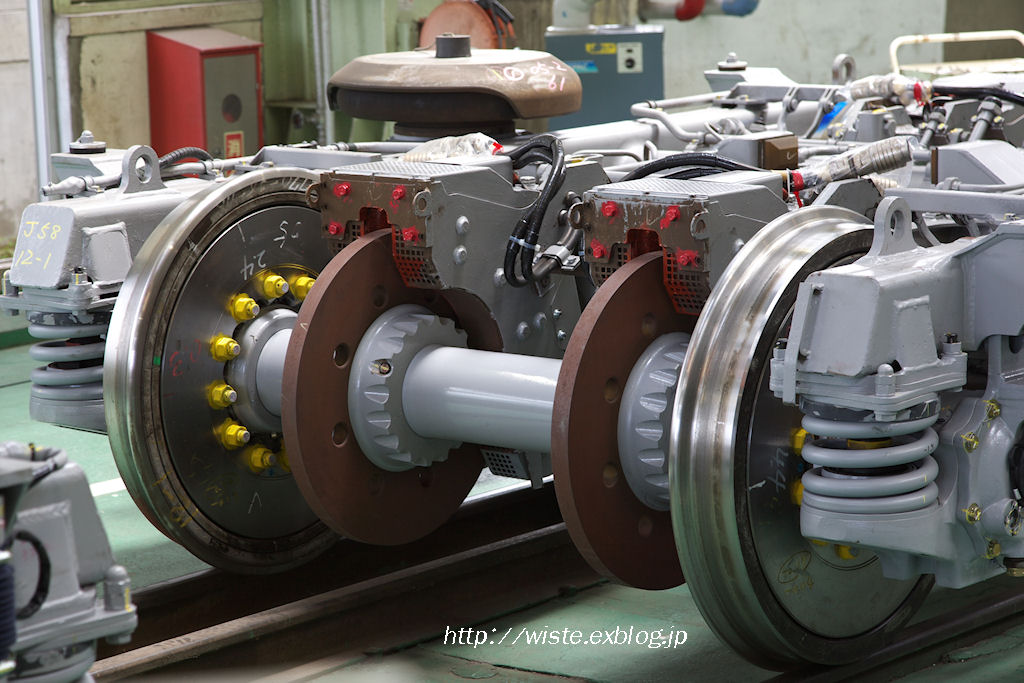

Disc brakes emerged as a response to these challenges. In a disc brake system, friction pads press against a disc mounted on the wheel or axle, rather than directly on the wheel tread. This design allows better heat dissipation, consistent braking performance, and reduced wear on wheels.

The practical applications appeared in the 1930s. In the United States, the Budd Company introduced disc brakes on the General Pershing Zephyr, which was a passenger train built in 1938 and placed into service in 1939. By the 1950s, disc brakes had become standard on new-generation passenger coaches and were later essential for high-speed trains such as the Shinkansen and TGV.

Modern Applications of Disc Brakes

Metro and EMU Systems

Disc brakes are widely used in modern metro trains and electric multiple units (EMUs), where frequent stops and starts demand reliable and consistent braking. In these systems, disc brakes are often combined with regenerative braking to recover energy and reduce wear on mechanical components.

LHB Coaches in India

In India, LHB (Linke-Hofmann-Busch) coaches have replaced older ICF coaches, which used traditional tread brakes. LHB coaches employ disc brakes to handle higher speeds

Eddy Current Brakes

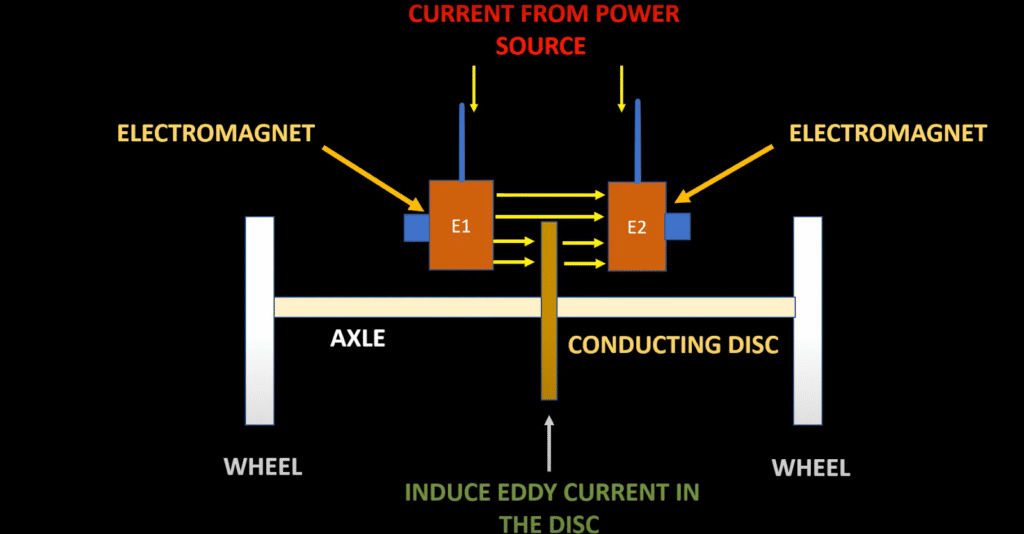

Eddy current brakes are a type of non-contact braking system that uses electromagnetic induction to slow down a train without physical friction. They are commonly used in high-speed trains, magnetic levitation (maglev) systems, and as supplementary braking systems where conventional mechanical brakes are less effective.

Working Principle of Eddy Current Brakes

Eddy current brakes operate on the principle of electromagnetism and provide contactless braking. A conductive disc is mounted on the axle, with electromagnets positioned near it. When the driver applies the brakes, the electromagnets are energised, creating a magnetic field. As the disc rotates through this field, eddy currents are induced in the disc. These currents generate an opposing magnetic field according to Lenz’s Law and produce a resistive force that slows the train without any physical contact.

Because braking is achieved through electromagnetic forces rather than friction, there is no wear on the wheels or brake pads. This makes the system especially suitable for high-speed trains and maglev vehicles. Eddy current brakes are generally used as supplementary brakes alongside mechanical brakes, particularly at high speeds where conventional brakes may overheat or become less effective.

Eddy current brakes offer several advantages, especially for high-speed rail applications. Since they operate without physical contact, there is no wear on wheels, brake pads, or discs, which reduces maintenance requirements. They perform efficiently at high speeds and provide smooth and consistent braking even when mechanical brakes might overheat. Additionally, because no friction is involved, the system operates quietly and vibration-free.

However, the Eddie Currentbrake system has some limitations. Eddy current braking force decreases at low speeds, so mechanical brakes are still needed for final stopping. Unlike regenerative braking, the energy is dissipated as heat and not reused in this system.

Magnetic Track Brake

Magnetic track brakes are a type of electromagnetic braking system commonly used in metros, light rail, and trams to provide rapid and reliable stopping, particularly in emergency situations. Unlike conventional brakes that act on wheels, magnetic track brakes act directly on the rail itself. MTBs are not the primary braking system but serve as a powerful, supplementary brake during emergencies or when adhesion between the wheel and rail is low.

Magnetic Track Brakes (MTBs) can deliver adhesion forces of up to 100 kN, which makes them effective even under challenging conditions. Modern MTBs are designed with a low profile, as small as 130 mm in height, to minimise space requirements and integrate easily into vehicle bogies. They are used as supplementary braking systems in high-speed trains, such as Germany’s ICE, where they operate alongside disc and regenerative brakes to ensure safe and reliable deceleration. MTBs are also extensively employed in metro and tram systems for emergency stops or rapid deceleration. Primary examples include the Delhi Metro, London Docklands Light Railway (DLR), and Munich U-Bahn, where they provide consistent braking performance even on wet or slippery tracks.

Integration with Safety and Train Control Systems

Modern braking systems do not operate in isolation. They are closely integrated with train safety and control mechanisms to ensure predictable and fail-safe operations. This integration allows braking systems to respond automatically to potential hazards to avoid any human error.

Automatic Train Protection (ATP) and Automatic Train Operation (ATO):

ATP systems continuously monitor train speed, track conditions, and signal aspects. If a train exceeds the permitted speed or approaches a danger point, the ATP system automatically triggers braking to prevent collisions.

ATO systems, used in metros and high-speed rail, control train acceleration and deceleration, including braking, to optimise schedules and maintain safe headways. Electro-pneumatic brakes and regenerative systems are particularly suited for ATO due to their fast response and precise control.

Indigenous Safety System in India:

- India’s Kavach system integrates with braking mechanisms to enhance train safety. If the driver fails to respond to a signal or an obstacle is detected on the track, Kavach can automatically activate the brakes, including E-P and disc brakes, to ensure that the train stops within a safe distance.

Limitations of Modern Braking Systems

Electro-Pneumatic (E-P) Brakes

E-P brakes rely on electrical signals to achieve fast and uniform braking across the train. This dependence on electricity makes them vulnerable to power failures or faults in the control wiring. While conventional pneumatic brakes serve as a backup, any malfunction in the electrical system can affect responsiveness, leading to a threat to safety.

Disc Brakes

Disc brakes perform well at higher speeds and provide consistent braking, but prolonged use generates heat that can lead to thermal stress and potential brake fade. In metro and suburban operations with frequent stops, friction pads experience accelerated wear, necessitating periodic replacement. Noise and vibration may also occur under certain conditions, although modern materials mitigate these issues to some extent.

Eddy Current Brakes

Eddy current brakes are highly effective at high speeds but lose efficiency at low speeds makes it necessary to rely on supplementary mechanical brakes for final stopping. The energy generated is dissipated as heat rather than recovered, which limits overall energy efficiency.

Magnetic Track Brakes (MTBs)

MTBs are designed primarily for emergency or supplementary braking rather than continuous service braking. They require high electrical power to achieve strong magnetic adhesion and, if they are used frequently, they can cause localised wear or damage to the rail surface.

Regenerative and Rheostatic Brakes:

Regenerative braking efficiency depends on the ability of the power network to absorb returned energy. When regeneration is not possible, rheostatic braking dissipates energy as heat, which creates thermal stress on resistors. Both systems require careful coordination with mechanical brakes to ensure safe stopping distances, particularly at low speeds or during emergency braking situations.

Emerging Business Opportunity in the Railway Braking Market

Global Market

As per the report released by Cognitive Market Research, the global railway braking systems market was valued at USD 9.25 billion in 2024 and is expected to grow at a compound annual growth rate (CAGR) of 4.0% from 2024 to 2031. North America is the largest market, contributing over 40% of global revenue (USD 3.69 billion), followed by Europe with more than 30% (USD 2.76 billion). The Asia-Pacific region holds around 23% of the market (USD 2.12 billion) and is expected to grow the fastest, at a CAGR of 6.0%. Latin America and Middle East & Africa account for smaller shares, with market sizes of USD 460.76 million and USD 184.30 million, growing at CAGRs of 3.4% and 3.7%, respectively.

India Market for Railway Brake Systems

The railway brake systems market in India was valued at USD 254.34 million in 2024 and is expected to grow at a CAGR of 7.8% during the forecast period. This growth rate is higher than both the global and regional averages. However the another research by Verified Market Reports suggests that

The main reasons for this increase are urbanisation, population growth, and government investment in railway infrastructure. Large projects such as high-speed rail, Dedicated Freight Corridors, and the rapid growth of metro networks in many cities are creating more demand for modern braking systems.

Older technologies, such as tread brakes on ICF coaches, are being replaced with disc brakes and electro-pneumatic brakes in LHB coaches and metro trains. At the same time, there is a move toward regenerative braking and integration with Automatic Train Operation (ATO) in new systems.

The focus on safety, efficiency, and reliability is influencing the market. India is gradually adopting braking systems that match international standards. This market trend creates opportunities for brake system manufacturers, suppliers, and rail operators to adopt and provide modern braking solutions across different regions.

Conclusion

As India enters a new era of mobility where speed and safety take the centre stage, modern braking systems are now a key part of railway safety and operations. Over time, brakes have moved from manual and vacuum systems to electro-pneumatic, disc, regenerative, eddy current, and magnetic track brakes. These changes have come with the need for higher train speeds, heavier loads, and stricter safety requirements. Modern systems also work with train protection and control systems, and in some cases, recover energy, which makes them more efficient than older brakes.

The global railway brake systems market was valued at USD 9.25 billion in 2024 and is expected to grow at a CAGR of 4.0% up to 2031. In India, the market was about USD 254.34 million in 2024 and is projected to grow faster, at a CAGR of 7.8%. This is driven by new metro projects, high-speed rail, and freight corridors. The demand for reliable and modern brakes will keep increasing as India and other countries expand their rail networks. For manufacturers and operators, this means there is a clear opportunity to supply advanced systems that meet both safety and performance needs.

To get real-time updates on metro and railway tenders, join our WhatsApp Community:https://chat.whatsapp.com/GP8MIGQ7fP6Eapgbm3d8og?mode=ems_copy_c

Explore how AI-integrated systems are improving comfort, connectivity, and accessibility for passengers across metro and rail networks at the 6th edition of InnoMetro, India’s leading expo for the Metro & Railway industry.

Date: 21-22 May 2026

Venue: Bharat Mandapam, New Delhi

Register now: https://innometro.com/visitor-registration/