SURAT (Metro Rail News): On 31 August, the construction of the first reinforced concrete (RC) track bed of the Mumbai-Ahmedabad bullet train project began in Surat.

The track system, which matches Japan’s Shinkansen bullet train, is introduced for the first time in India using the J-slab ballastless track system, as stated by an official document.

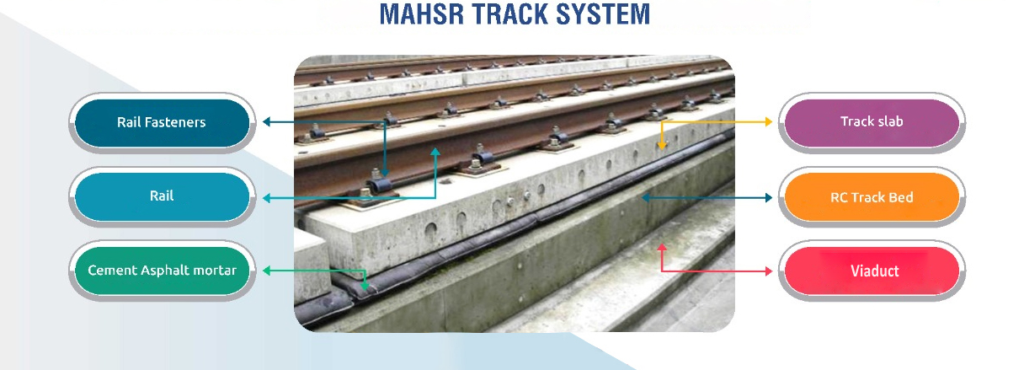

The track system is composed of a pre-cast track slab over which fastening devices and rails are affixed. This slab rests on the RC track bed, which has a thickness of approx 300mm and is constructed on-site for each individual UP and Down track line situated atop the viaduct. The width of the RC track bed measures 2420 mm.

To ensure the stability and functionality of the track slab, RC anchors are strategically placed to prevent any longitudinal and lateral movements. The RC anchor has a diameter of 520 mm and stands at a height of 260 mm. These are built at approx. 5 m centre to centre.

Within the RC anchors, reference pins are installed to attain the desired alignment, both horizontally and vertically, which is essential for train operations at speeds of up to 320 kmph.

Contracts for the track works in the entire Gujarat region have been awarded, and the procurement of materials for track construction is currently in an advanced stage. Over 14,000 metric tons of JIS rails and 50 molds for casting track slabs have already been imported from Japan.

Manufacturing of the track slabs will take place in specialized factories, with two such facilities already established. These factories are equipped with cutting-edge technology and infrastructure to ensure the precise production of slabs for the High-Speed Rail (HSR) track construction.

The construction process will involve the use of special machinery, including rail feeder cars, slab laying cars, and CAM (Cement Asphalt Mortar) laying cars.

To ensure that the Indian contractors are well-prepared for the task at hand, an extensive training and certification program is being organized in collaboration with Japan Railway Technical Services (JARTS) as the Training & Certification agency. This initiative aims to familiarize the personnel with the execution methodology related to track laying for this groundbreaking project.